A lot of energy is still being wasted in lighting. Thankfully, more economical LED bulbs use much less energy than the old incandescent bulbs that produced mostly heat, along with the desired illumination. But we must continue to see where we can improve.

To protect our climate, the EU plans to use 260TWh less energy by 2030. That’s a lot. Lighting is supposed to make up 16% of that. So, much more efficient lamps will be needed to achieve this goal. In order to make this transition possible, adequate monitoring is needed, which will allow the comparison of products in terms of technology used, efficiency, and power consumption. A way to ensure that all producers make information available in the same way, allowing users to choose the best solution. This market demand for efficiency will reduce overall energy consumption.

Just like with fridges or dishwashers, LEDs come in a variety of forms. And some LEDs are much more energy-efficient than others. But it can require a lot of effort to get to the bottom of the diverse product features to fully understand the differences.

New uniform labels

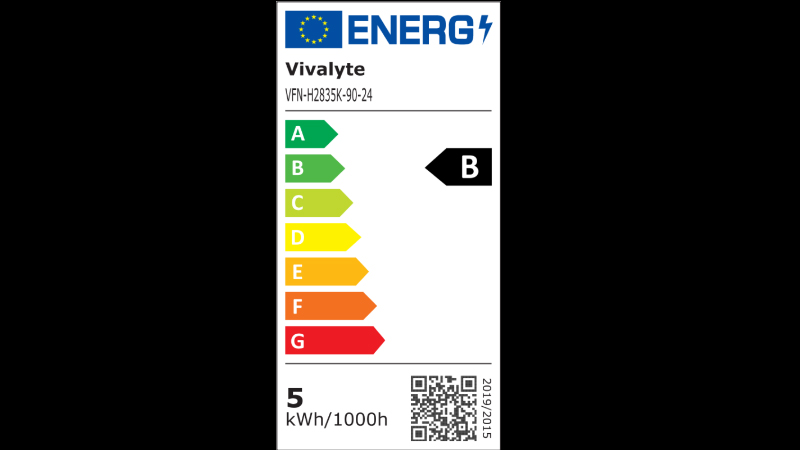

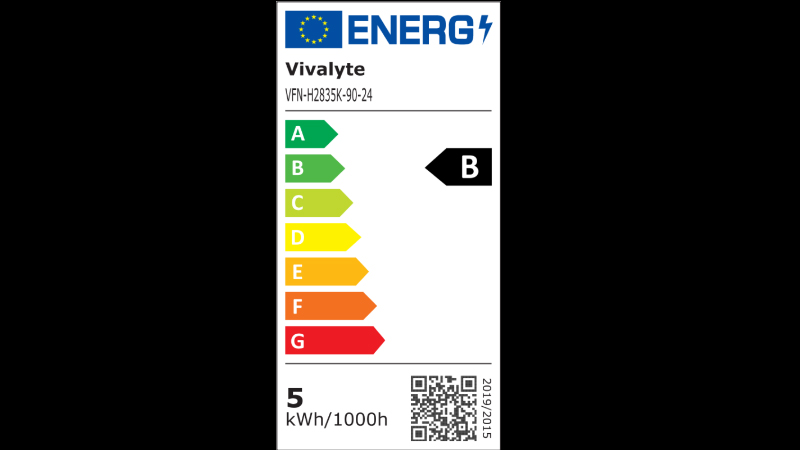

That’s why the European Union requires manufacturers to label their products with a uniform label that complies with legal regulations. That’s how we got the energy labels. A refrigerator of energy class B, or a dishwasher of class A++. The regulatory authority for these labels is also known as EPREL: the European Product Registry for Energy Labelling.

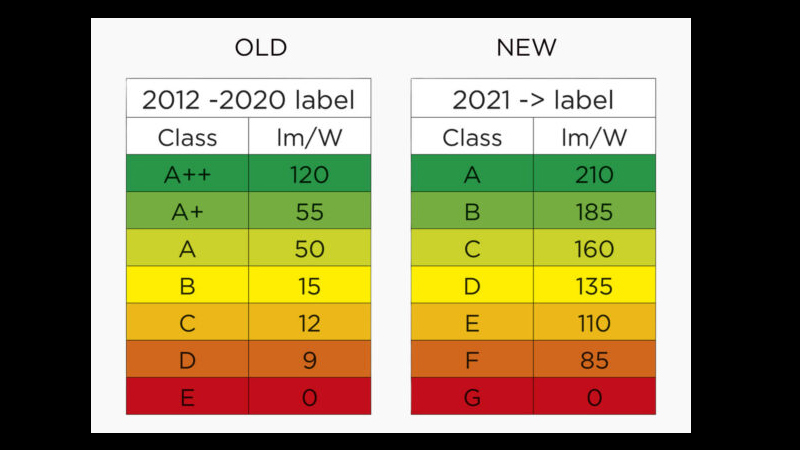

LED lamps must also be labeled with the corresponding energy efficiency class. But as LED bulbs quickly became much more efficient in recent years, very many fell into the higher classes.

To give consumers the necessary clarity with their purchases, the classes have been significantly revised. As a result, lamps that were previously in class A++ may now fall into class D, for example, because the new requirements are very demanding.

Keep in mind that LEDs that have a lower rating on their new label have not become less efficient – they are consuming the same amount of power as they always have, but have dropped some classes. Light sources that don’t reach a minimum efficacy will be prohibited from being sold.

The energy efficiency class of light sources is determined on the basis of the total mains efficacy ηTM, which is calculated by dividing the declared useful luminous flux Φuse (expressed in lm) by the declared on-mode power consumption Pon (expressed in W) and multiplying by the applicable factor FTM.

To correctly compare different types of light (directional or non-directional, operating on mains or not), the total mains efficacy is multiplied by the applicable factor for the type of light.

Besides the energy efficiency class, the labels now also feature a QR code. When you scan that code, you can check all the technical data of that led lamp. Standardized information on:

Focus, color, glare, angle of the light beam, color temperature

Mains voltage, energy consumption,

Dimensions, dimmability, spectral distribution, flicker

…

On the left, you can see a label according to the new EPREL regulations for an efficient LED lamp from Vivalyte (the VFN-H2835-90 24V) with a light output of more than 210 lumens per watt.

As a pioneer in innovation, Vivalyte has been looking for more efficient LEDs for some time. We are proud to announce that we are one of the first suppliers in the world to offer LEDs that meet the requirements for the B and C category. (There are currently no A-rated lamps available anywhere).

Even compared to the most recent efficient LEDs that came on the market in the last 2-3 years (the popular 2835 series with a 100-140lm/W), the new Vivalyte LEDs score almost double the light output!

That’s a huge difference. For installations that require high light output and are running for many hours each day, the gain is quickly significant. So we are very pleased to be able to offer our customers this great gain in efficiency that will certainly have a positive impact on their energy costs.

For an installation of 30m2 the decrease from 50W/m2 to 20W/m2 end up costing a lot less energy. With an industry average of 3960 hours of operation a year and a price of €0.24 per kWh the cost is reduced from €1425 to €570, just for the LEDs.

Of course, we have to take into account a change in whole bunch of other costs associated with a lighting installation. More efficient LEDs produce a lot less heat, which means significantly less cooling is required, resulting in further savings. There are also fewer requirements for the electrical system which again reduces costs. Further, consider reduced HVAC costs to keep rooms at a comfortable temperature, better shelf life of perishable products or less stringent insurance needs.

It quickly becomes clear that more efficient LEDs have a big impact on signage and marketing budgets. The higher efficiency in light output is the basis for a much lower TCO (Total Cost of Ownership).

The reduced need for energy for these lighting installations will also be of immediate benefit to the environment. And this was exactly the aim of these new EPREL classifications and underlying regulations.